SMES Manual

![]()

![]() Superconducting Magnetic Energy Storage (often shortened to SMES) is a device used to store electrical power. While SMES units are very effective, they are also expensive, requiring high end circuit board and expensive parts. If you need to quickly replace the SMES you may try using cheaper but less powerful Cell Rack PSU instead. SMES units may be upgraded to increase their capacity and/or maximal input/output levels.

Superconducting Magnetic Energy Storage (often shortened to SMES) is a device used to store electrical power. While SMES units are very effective, they are also expensive, requiring high end circuit board and expensive parts. If you need to quickly replace the SMES you may try using cheaper but less powerful Cell Rack PSU instead. SMES units may be upgraded to increase their capacity and/or maximal input/output levels.

Configuration

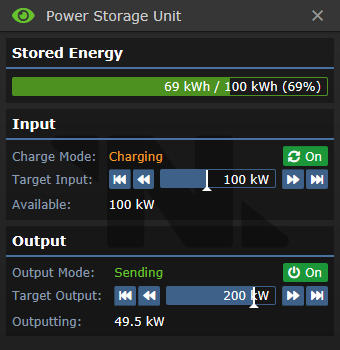

SMES units may be configured via interface which is opened by left-clicking with empty hand on the SMES. Alternatively you may use the RCON (Remote CONtrol) console to operate most SMESs on station. The interface looks like this:

Input

Each SMES needs a terminal to operate properly. This terminal allows you to charge the SMES from one power network and output into another one. By using appropriate controls in the GUI you may set any input value up to certain cap determined by the magnetic coils installed. This cap can be increased by upgrading the SMES unit, as described further in this guide. Also, please note that setting larger input than available will cause the SMES to enter a "Partially Charging" state. This means the SMES is still charging, but there is not enough power available to charge at the set input rate. You may choose from two input options - OFF and ON, toggled by clicking the button next to the 'charging mode' and charging status readout.

Output

The SMES outputs power into the wire knot placed directly under it. Generally speaking you want the main SMES charged directly by the Engine to have a higher input than output. In some instances you may want to have an SMES input limit be lower than its output limit, such as when setting Substations. This will allow the substation to charge at a reasonable rate without hogging all the available power, but also allow its output to compensate for power spikes such as when short term high demand equipment is used. The output rate is also capped and can be upgraded. You may choose from two output options which are self explanatory - OFF and ON.

Values

See also: Guide to Power

There are multiple ways to change the values in the SMES interface. The 'target' will set the limit on how much power can go in or out of the SMES. The arrows on either side of the target slider will increase or decrease the target value. Clicking and dragging the target slider will allow fine tuning the target. Finally, clicking on the target slider once will change it to a numerical input.

These are example settings for few SMESs around the station. You may choose different settings, depending on available power and other factors. Try to consult the Chief Engineer when unsure.

| Location | Input | Output | Other notes |

|---|---|---|---|

| Engine - Core | 250kW | 250kW | Above everything else it is imperative that the engine SMES remains charged and has its in/output enabled to prevent catastrophic engine failure |

| Power - Main | 1000kW | 950kW | You may have to lower the output if engine is producing less power. Try to have more power coming in than is going out when possible. |

| Atmospherics | 250kW | 250kW | Some things, especially pumps, use large amounts of power. This means atmospherics needs a lot of power. |

| Substations | Variable | Variable | Refer to page Substations for more information. |

Deconstruction

Required tools

Screwdriver

Screwdriver Crowbar

Crowbar Wirecutters

Wirecutters Welding Tool

Welding Tool Wrench

Wrench Insulated Gloves (optional, but recommended)

Insulated Gloves (optional, but recommended) Multitool (optional, only if you decide to disable failsafes)

Multitool (optional, only if you decide to disable failsafes)

Preparations

- First of all you should ensure the SMES is discharged. While there is a workaround, it may (read: will) cause an injury and/or damage.

- Open the SMES's interface by left clicking it. Ensure both Input and Output are turned Off.

- Use screwdriver on the SMES to open the access panel.

- Use wirecutters on the SMES to cut the terminal. If the terminal is missing (or destroyed) simply skip this step.

Deconstruction Steps

- Complete everything in Preparations

- (OPTIONAL) Use multitool on the SMES to disconnect safety circuit. This step may be skipped if you completely discharged the SMES. DO NOT PROCEED IF SMES IS CHARGED ABOVE 50%, usually, anything below 15% is safe(with gloves). Anything above 50% is likely to kill you.

- Use crowbar on the SMES to begin removing the components. This may take up to 60 seconds, depending on amount of coils in the SMES. Basic SMESs should take approximately 10 seconds. SMES will turn into machine frame and few components. You may use these components for research or for repairs/upgrades.

- Use wirecutters to remove cables from the machine frame

- Use wrench to dismantle the machine frame

SMES Failure

Disabling failsafes, as outlined in Hacking section of this page may cause SMES Failure when removing the components (crowbar step), or adding new components (inserting new coils). Chance of "something bad" happening is directly proportional to SMES charge percentage. SMES charged to 75% has 75% probability of failing, etc. If this failure happens, effects are once again related to charge percentage.

- Discharge - (Always) The SMES will lose ALL it's remaining charge.

- Sparks - (Always) Mostly harmless, some sparks will fly from the SMES, potentially igniting fire if flammable material is nearby.

- Electrocution - (Always) Shocks the user. Please note that while insulated gloves mitigate the effect, they aren't guaranteed to 100% protect you. Damage scales with charge percentage. Anything above 60% charge is instant-kill even with gloves.

- EM Pulse - (above 15% charge) Causes electromagnetic pulse which breaks nearby electronics. This usually trips fire alarms, breaks consoles, and may even kill/injure the AI/cyborgs/people with prosthetics depending on situation. Size of EM Pulse is proportional to amount of stored power.

- APC Overload - (above 35% charge) Overloads lighting circuits of few APCs connected to the SMES's output. Please note that having something between the SMES and APC (such as, another SMES) will prevent the damage. Chance is proportional to amount of stored power.

- APC Failure - (above 35% charge) Completely breaks few APCs in SMES's output. Same rule as above applies.

- Magnetic Containment Failure - (above 60% charge) The worst thing that can happen. If SMES's magnetic containment fails remaining charge is released in form of violent explosion. The SMES is completely destroyed, as well as few nearby tiles. This almost always causes hull breach, and the explosion may gib you. After this failure is triggered you have 30-60 seconds before the SMES blows up.

Hacking

SMES units may be hacked to enable or disable various features. Remember to wear your ![]() protective equipment or risk injury. To access the wiring open front panel with screwdriver. Then click the SMES with empty hand to open up wiring window. There are five wires, which have randomized colours every round.

protective equipment or risk injury. To access the wiring open front panel with screwdriver. Then click the SMES with empty hand to open up wiring window. There are five wires, which have randomized colours every round.

- Input - Cutting this will cause the SMES to stop inputting. Pulsing will temporarily disable input.

- Output - Cutting this will cause the SMES to stop outputting. Pulsing will temporarily disable output.

- RCON - Cutting this will disable RCON (Remote CONtrol), hiding the SMES from control consoles. It also disables AI control. Pulsing does nothing.

- Failsafes - Cutting will allow you to modify the SMES even if it is charged. Please note that this may result in catastrophic overload if charge is large enough. Pulsing does nothing.

- Grounding - Cutting or pulsing this wire will overload the SMES, causing quick dissipation of stored energy. This energy may however damage or destroy APCs in output power network, so it is advised to either disconnect the SMES, or at least use Guide to Power#SMES_SettingsSubstations to prevent damage to many APCs. Mending will restore grounding and stop the overload. This is highly similar failure of charged SMES, but with less risks involved for the user. Remember that doing this as non-antagonist is not a good idea.

Construction

Required Tools

Cable Coil, 2x (two full coils)

Cable Coil, 2x (two full coils) Metal Sheets, 5x

Metal Sheets, 5x SMES Circuit Board - May be obtained from Research, or salvaged from existing SMESs

SMES Circuit Board - May be obtained from Research, or salvaged from existing SMESs Superconducting Magnetic Coil - May be obtained from Cargo or salvaged from existing SMES. This can be any of the four types of coils. While one coil is needed to initially construct the SMES, you may add up to six coils into single SMES.

Superconducting Magnetic Coil - May be obtained from Cargo or salvaged from existing SMES. This can be any of the four types of coils. While one coil is needed to initially construct the SMES, you may add up to six coils into single SMES. Insulated Gloves - Optional, but recommended (especially if you are going to manipulate wiring)

Insulated Gloves - Optional, but recommended (especially if you are going to manipulate wiring)

Construction Steps

- Use your metal sheets to build frame parts, then use the frame parts to build a machine frame.

- Wrench the machine frame to the floor in the desired location.

- Add the SMES Circuit Board, then use a screwdriver to secure it.

- Use cable coil on the machine to add wires.

- (RECOMMENDED) place a wire knot under the machine frame if one is not already present. The SMES will output into this wire.

- Add 30 pieces of cable (one full length cable coil).

- Add one superconducting magnetic coil of any variety.

- Finalize the SMES with screwdriver.

Terminal

New SMES starts without terminal, which allows the SMES to draw power from a network. Furthermore, terminals may be damaged by explosions or similar effects. Fortunately, installing new terminal is easy.

- Open interface of your SMES and turn it's input and output OFF.

- Use screwdriver on the SMES to open the cover.

- Use cable coil on the SMES to add new terminal. You need 10 pieces of cable for this. If you make a mistake use wirecutters to remove the terminal and repeat this step.

- Use screwdriver on the SMES to close the cover.

RCON Settings

RCON, or Remote CONtrol, allows remote operation of SMESs from RCON console. To allow usage of RCON you have to set RCON tag. This tag has to be unique (ie. do not use tag already used by another SMES). To set new tag click the SMES with multitool. If you wish to disable RCON you may either cut apropriate wire (see Hacking section), or use tag "NO_TAG".

Upgrading

The level at which a SMES can input or output energy (throughput) and how much energy it can store (capacity) is based on the coils installed inside the unit. There's no penalty for mixing different coils. To place coils inside a SMES, unscrew the maintenance panel and simply place them inside, but the SMES has to be completely discharged, otherwise the safety mechanism will prevent you from placing any coils inside (and it's probably a good thing, otherwise you'll explode from arc flash). If you wish to upgrade all of the coils in an existing SMES you will need to deconstruct it up until its components are placed onto the floor beneath the machine frame.

The level at which a SMES can input or output energy (throughput) and how much energy it can store (capacity) is based on the coils installed inside the unit. There's no penalty for mixing different coils. To place coils inside a SMES, unscrew the maintenance panel and simply place them inside, but the SMES has to be completely discharged, otherwise the safety mechanism will prevent you from placing any coils inside (and it's probably a good thing, otherwise you'll explode from arc flash). If you wish to upgrade all of the coils in an existing SMES you will need to deconstruct it up until its components are placed onto the floor beneath the machine frame.

There are three (technically four) types of coils in existence:

| Coil type | Capacity kWh | Throughput kW |

|---|---|---|

| Superconductive Magnetic Coil | 100 | 250 |

| Superconductive Transmission Coil | 10 | 1000 |

| Superconductive Capacitance Coil | 1000 | 50 |

| Basic Superconductive Magnetic Coil* | 20 | 150 |

*The basic coil is not obtainable by ordinary means.

There are two of each type of coils as well as two circuitboards in the Engineering Hard Storage, in one of the crates.

When building a SMES you may add only a single Magnetic Coil of any type into it. However, you may add up to five more coils later. This process is slightly more complex than terminal replacement.

- Ensure the SMES is discharged. Alternatively, you may disable the failsafes (see point 4.). Please read the "SMES Failure" section of this guide before proceeding.

- Open interface of your SMES and turn it's input and output OFF.

- Use screwdriver on the SMES to open the cover.

- (OPTIONAL) Disable failsafes by cutting the correct wire (see Hacking section).

- Use your superconducting magnetic coil(s) on the SMES to install them.

- (OPTIONAL) Re-enable failsafes if you disabled them.

- Use screwdriver on the SMES to close the cover.

Most SMES around the station contain a single coil, however the main SMES typically has 4 already installed, leaving room for 2 more coils. If replacing all the coils is desired the machine must be deconstructed to the point the coils are removed and placed on the floor below.